Design

Description, Analysis and Calculation of

Micro Hot Point Improved Biomass Stove

of

Sai

Grameen Udyog

Faridabad,

Haryana

By

Bibhu Prasad Mohanty

Good Will Promoter Of Micro Hot Point Improved Biomass Stove

bibhu65@gmail.com

Design

Description

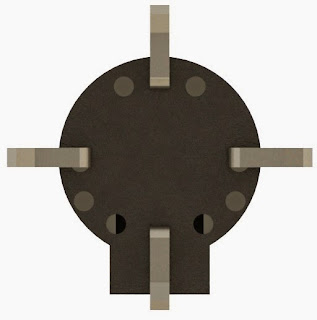

The

Micro

Hot Point Improved Biomass Stove

generally consists of a combustion chamber, a top section and a

base. The hearth of the combustion chamber is made of perforated

stainless steel plate

,

the outside of which encased in a mild steel casing. The grate or

fuel bed is at the base of the combustion chamber. The base of the

stove consists of a door for loading fuel wood into the combustion

chamber, and few

whole in the base

which serve as combustion air inlets to the chamber. A drawer is

incorporated at the base to facilitate the removal of ash which would

have collected at the tray. The top of the stove consists of the pot

seat, designed

to accomodate any type heating utensils. The

pot seat is designed such that the pot sinks to a depth below the

top- most level of the stove. The stainless

sttel ring

selected for use is such that has the internal diameter equal to or

closest to the external diameter of the cooking pot, thus ensuring

that there is little or no clearance for

pass above the pot seat.

The diameter of the combustion chamber is such that it is smaller

than the pot seat or the external diameter of the smallest pot that

can be utilized on the stove. This is to ensure that the maximum

amount of heat is transferred to the base of the pot . The distance

between the fuel bed and the pot seat is also selected to allow for

enough time for the complete combustion of the burning fuel particles

before it strikes the base of the pot mounted on the pot seat.

Combustion

Air Requirement

Following

Ramakrishna (1992), a typical fuel wood has the following ultimate

analysis by mass as shown in Table 1.

Table

1. Mass analysis of a typical fuel wood.

C

|

H2

|

O2

|

N2

|

H2O

|

Ash

|

40.4%

|

4.2%

|

33.9%

|

0.3%

|

20%

|

0.2%

|

The

combustion analysis based on the above mass composition gives a

stoichiometric Air/Fuel ratio, A/F= 4.6107 kg air/kg fuel. For an

actual air supply which is 20% in excess of stoichiometry, actual

air/fuel ratio, A/Factual=

5.53284 kg air/kg fuel.

Key

Features of Micro

Hot Point Improved Biomass Stove :

Single burner Height 12 inches Stainless Steel Combustion Chamber

Bakelite handles Durable steel construction No moving parts Light

weight (4kg) Removes need to blow on fire

Performance

Parameters:

- Thermal Efficiency 25.4%

- CO/CO2 Ratio 0.02

- Output Thermal Wattage 1.2kW

- Burning Capacity 0.8-1.1 kg/hr.

- Average Product Lifespan: 5 years.

Discussion

of Results of

different tests

The

results as

per the test protocols of IIT, New Delhi show

that the biomass stove has a maximum thermal efficiency of 25.4%

and power delivery of 1.4kW,

but a minimum specific fuel consumption of 0.492.

This indicates a better performance when compared to the average

thermal efficiency value of 17.9% for traditional mud stove as

reported by George (1997), or the Kilakala stove which has a fuel

saving capacity of 30% (Crewe 1990, Otiti 1991). The performance is

also better when compared to the Improved Vented Mud stove (IVM)

which has the average thermal efficiency values across fuels that

varies from 10% to 23% which is comparable with the range of 10.8% to

19.6% reported by Pal and Joshi (1989). Furthermore, the thermal

efficiency of the wood stove is not higher when compared to the

thermal efficiencies of petroleum based fuel stoves such as the LPG

stove, the kerosene wick stove, and the kerosene pressure stove with

thermal efficiencies of 53.6%, 50% and 47%, respectively (TERI 1987).

Enahnced

Performance:-The

enhanced performance can be attributed to a number of factors. The

first is the insulation provided round the combustion chamber. This

minimizes the rate of heat loss across the wall of the combustion

chamber by conduction and radiation,and ensures that a good

proportion of heat is conserved within the chamber and directed

towards the top of the chamber. The second is the smoke rings

provided which eliminate the horizontal clearance between the pot and

the pothole. This minimizes heat loss by radiation through the

annulus between the pot and the pothole. The third factor is the

design of the pot seat and the position of the flue gas exit port

This ensures that the base of the pot sinks to a depth inside the

pothole such that there is no vertical clearance between the pot base

and the top of the stove, and that there is longer interaction

between the flame and the pot base, bringing about maximum heat

transfer to the pot, before the flue gases exit into the chimney.

There is also the factor of availability of sufficient air that

ensures the complete combustion of the fuel wood. On smokiness, it

was observed that virtually all the flue gases was conveyed out of

the test area through the chimney. The very small quantity of smoke

noticed might have escaped as a result of construction inaccuracy in

the roundness of the smoke rings leaving a very small gap between the

pot and the ring. The escaping smoke, however, quickly diffuses into

the air, causing insignificant fouling and irritation effects. It

would be seen that the modifications made in providing insulation

around the combustion chamber and sizable air inlet from

base to

admit adequate quantity of air for combustion, incorporating smoke

rings to seal the annulus between the stainless

steel pot

and the pothole, and redesigning the configuration of the pot seat

and the position of the flue gas exit port, have served to increase

the thermal efficiency and therefore the percentage heat utilization

of the stove. There has also been a drastic reduction in the

smokiness of the stove, making it to be more user-friendly in health,

comfort and convenience. Further modifications focused at redesigning

the pot seat vis-à-vis the flue gas exit port in such a way that

will minimize heat loss by radiation and convection, and ensure

maximum heat transfer to the base of the pot can be pursued in future

How

to operate

it:- Fill the fuel

wood entrance with dry wood. Then fill the inner cavity of the chula

from the top with dry small twigs, dry leaves and fire those from

top. There is no need of

ferosene at all. Within 2

minutes chula will be ready for cooking. It

has very less smoke,

saving of at least 65% fuel. That takes care of household indoor

atmosphere. Small kitchens of rural houses remain free from fumes and

congesting carbon monoxide, carbon dioxide and other harmful smokes.

Fuel

wood smoke from kitchen in rural households is a major reason of bad

health of women and children both. It

is observed that the smoke of fuel wood is equivalent to 70-150

cigarettes per day.

Advantages

of Micro Hotpoint Improved

Biomass Smart cook

stove as compared to traditional mud stove/ three stone fires:

Less

Fuel:

- 70% less consumption of fuel

- Reduces drudgery of women collecting fuel wood

- Reduced deforestation due to less consumption of fuel wood

- Reduces dependency on plant fuel wood

Less

Smoke:

- 65% reduction in smoke (particulate matter)

- Beneficial in terms of reduced Indoor Air Pollution (IAP) and healthier environment for women and children

- Reduces global warming due to reduction of black carbon and other warming agents

- Very less blackening of cooking pots and kitchen walls due to negligible cabon shooting

Less

Cooking Time:

- Reduces the cooking time by approximately half

- Less exposure of women to kitchen smoke so people around cooking place do not feel fatigue due to smoke

- More time for economic/ recreational activities

Local

Fuel:

- Locally available solid biomass used as fuel. Mostly dry twigs, dry leaves, dry cowdung cake, dry other animal dungs, crop wastes, tree wastes, after use wastes from biomasses.

- The fuel required does not demand the establishment of separate fuel supply chains and facilitates local biomasses insignficant for fuel purpose

- Timely and easy availability of cooking fuel around the household area. Thus it improves the autonomy of woman over kitchen.

Environmental

benefits

This

Smart stove meets the several Indian standards for efficiency and

emissions. Testing and user feedback suggest that the Smart stove

wood and neglected fuel biomas uses from an average of 1.1 kg per

hour , thus saving 2.1 tonnes/year per household. There is huge

pressure on wood resources in the India . Indian Ministry of Energy

and Fuel estimates that 73% of wood comes from deforestation

(non-renewable sources).Each stove reduces the equivalent of between

1.5 tons of carbon dioxide emissions annually. Reduces Carbon

Monoxide, other harmful emissions and indoor air pollution level

helps to manage their health of women living in rural area,